The vibrating fork level switch working principle is simple and effective. This makes vibrating fork level switch reliable, cost effective and very popular for use in detecting the presence or absence of liquids and bulk solid materials. The vibrating fork level switch working principle is based upon detecting the changein harmonic vibration frequency of the sensing element as a result of the presence of the target media.

The vibrating fork level switch working principle uses a tuning fork shaped sensing element with two tines inserted into the bin or tank where the target media will be present. The turning fork sensing element is placed into vibration at its natural resonant frequency by establishing motion in the vibrating fork level switch working principle the harmonic vibration of turning fork sensing element is established using piezoelectricity.

USE

-

High, low and intermediate level indication in tanks

-

Tank fill/ empty control

-

PLC/DCS level sensing input

-

Level detection in plastic or metallic tanks

-

Compact and small tanks and surroundings

INDUSTRY

-

Water

-

Solvents

-

Chemical

-

Food & beverage

-

Many other

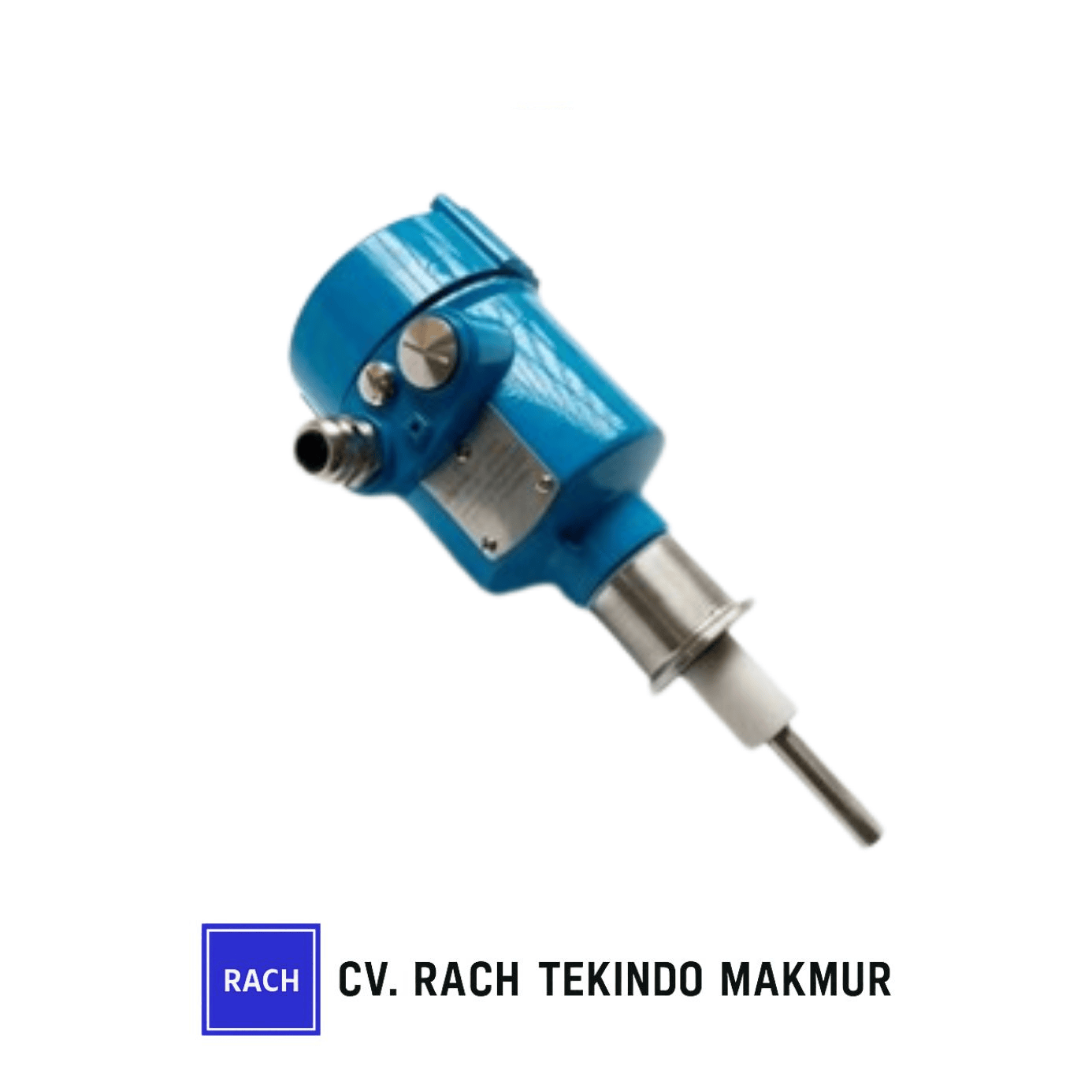

Casing: Cast Aluminum, IP65 weatherproof, ATEX IP68 explosion-proof

Connection: Threaded, flanged, on request

Temperature: -40ºC to +80ºC / High temperature version 500ºC.

Power Consumption: Approximately 3 VA

Electric Voltage: 24VDC, 220VAC

Output: DPDT 220VAC/5A, NPN/PNP